Introducing Our Innovative Biological Sewage Treatment Systems

In a world where environmental consciousness and maritime sustainability are paramount, the need for responsible sewage treatment solutions has never been greater. Our generation demands action, and our future depends on it. Moreover, in today’s fiercely competitive landscape, cost-effective operation is a top priority for fleet owners and the shipbuilding industry. Meeting these dual challenges requires a flexible and efficient solution. With this vision at heart, Holland Marine Services Amsterdam proudly presents its groundbreaking line of advanced biological sewage treatment systems.

Key Features of our MSD-III Series:

Certifications: Our systems have earned the prestigious Type approval from both Lloyd’s and the Netherlands Shipping Inspectorate, along with MED IMO/Marpol certification.

Competitive Product Range: We offer a comprehensive and cost-effective standard product range that caters to various needs.

Immediate Availability: All our standard systems are promptly delivered.

Customization: We specialize in tailor-made solutions, with the ability to construct systems to accommodate up to 400 people, meeting your specific requirements.

Strategic Production Facility: Our strategically located production facility in Amsterdam, the Netherlands guarantees reliable and on-time deliveries.

Compact Efficiency: Our systems feature the most compact biological process, resulting in low sludge production and simple, reliable process control thanks to the patented Fixed Activated Sludge Technology (FAST®).

Cutting-Edge Disinfection: We offer a unique combination of chemical-free disinfection methods and an advanced Post-Filtration Systems.

Compatibility: Our systems seamlessly integrate with all vacuum-collecting system brands, ensuring versatility and convenience.

Cost-Effective Reliability: We provide a one-stop solution, becoming your single supplier for the entire installation, ensuring cost-effectiveness and reliability.

Global Service Network: Count on us for worldwide round-the-clock service and repairs, all conducted by our own expert engineers.

Holland Marine Services Amsterdam serves shipyards and shipowners worldwide through a network of dedicated agents. We cater to all types of projects, offering a comprehensive range of standard designs while also delivering custom solutions tailored to your specific needs, whether for commercial vessels, accommodation barges, FPSO vessels, drilling rigs, or luxury yachts.

All our products are manufactured and assembled in the workshop of our sister company, Holland Repair and Services in Amsterdam, under our vigilant supervision. They are fully compliant with present IMO/Marpol MEPC.2 (VI) and MED96/98/EC regulations, affording us unparalleled quality control. Our MCA/MED quality control system, as approved and certified by Lloyd’s, ensures the highest standards in our products.

Rest assured, our Lloyd’s and Netherlands Shipping Inspection Type Approval on the biological sewage treatment plant design parameters, IMO certificate, SBG certificate, MCA/MED certificate, and USCG admittance for vessels visiting the USA, make our Type Approval certificates universally accepted by all major Classification Societies.

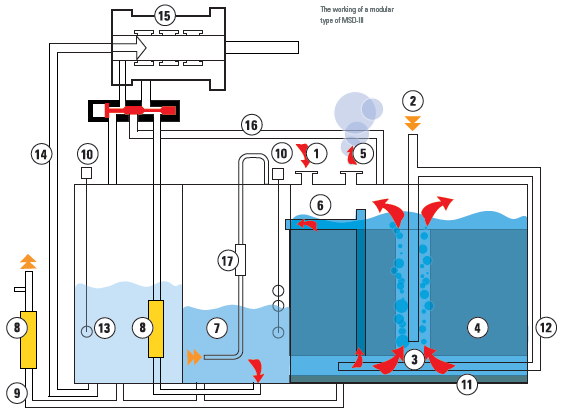

The operating principle of the MSD-III biological sewage treatment system

Waste water enters the system at the inlet (1). The blower (2) provides air and causes the waste water to circulate through the submerged fixed media (4) by means of the airlift (3), a simple but reliable mammoth-pump principle. The micro-organisms that grow on the surface of the fixed media break down the organic particles in the waste water biologically. Treated water flows to the sump tank (7) via the spillover (6). The copper-silver ionization unit (17) releases precisely measured doses copper and silver ions as to eliminate most bacteria and viruses already and prevent fouling in the system. The result is high-quality treatment coefficients and effluent that is suitable for UV (8) radiation and post-filtration (15) before being discharged overboard. The back flush pump (14) automatically cleans the post-filtration unit, timer and differential pressure controlled. Grey water can enter the unit either through an optional grey water inlet for post-filtration only, or through the inlet (1) for biological treatment. The discharge pump (9) and level switches (10) automatically maintain substance levels in the back flush tank (13). A limited amount of sludge (11) settles at the bottom of the unit and can be released through air (12) and discharged by the discharge pump (9).

| Specifications Biological Sewage Treatment units, MSD-II series standard units | ||||||

|---|---|---|---|---|---|---|

| Type ** | Dimensions L x W x H | Nos. of person | Weight | Hydraulic load | Organic load | Power consumption |

| MSD-III/10 | 1,310 x 1,000 x 1,599 | 11 | 490 kg | 0,83 m³ / day | 0,44 kgBOD / day | 3 kW |

| MSD-III/20 | 2,100 x 1,000 x 1,790 | 23 | 720 kg | 1,65 m³ / day | 0,92 kgBOD / day | 4 kW |

| MSD-III/30 | 2,100 x 1,300 x 1,790 | 35 | 850 kg | 2,48 m³ / day | 1,40 kgBOD / day | 4 kW |

| MSD-III/40 | 2,100 x 1,550 x 1,790 | 47 | 1.015 kg | 3,30 m³ / day | 1,90 kgBOD / day | 5 kW |

| MSD-III/50 | 2,450 x 1,550 x 1,790 | 58 | 1.090 kg | 4,10 m³ / day | 2,32 kgBOD / day | 5 kW |

| MSD-III/60 | 1.270 x 1,550 x 1,790 | 70 | 1.200 kg | 4,95 m³ / day | 2,80 kgBOD / day | 5 kW |

| MSD-III/70 | 3.200 x 1,550 x 1,790 | 82 | 1.380 kg | 5,78 m³ / day | 3,30 kgBOD / day | 5 kW |

| MSD-III/80 | 2,200 x 1,600 x 2,402 | 94 | 1.680 kg | 6,60 m³ / day | 3,76 kgBOD / day | 6 kW |

| MSD-III/100 | 2,500 x 1,600 x 2,402 | 117 | 1.870 kg | 8,25 m³ / day | 4,68 kgBOD / day | 7 kW |

| MSD-III/120 | 2,900 x 1,600 x 2,402 | 141 | 2.130 kg | 9,89 m³ / day | 5,64 kgBOD / day | 7 kW |

| MSD-III/140 | 3,300 x 1,600 x 2,402 | 164 | 2.355 kg | 11,54 m³ / day | 6,56 kgBOD / day | 8 kW |

| MSD-III/160 | 3,700 x 1,600 x 2,402 | 188 | 2.550 kg | 13,22 m³ / day | 7,52 kgBOD / day | 8 kW |

| MSD-III/200 | 3,700 x 1,990 x 2,408 | 235 | 3.620 kg | 16,50 m³ / day | 9,40 kgBOD / day | 10 kW |

| MSD-III/240 | 4,190 x 2290 x 2,408 | 282 | 4.620 kg | 19,79 m³ / day | 11,28 kgBOD / day | 11 kW |

| MSD-III/280 | 4,190 x 2,590 x 2,408 | 330 | 4.816 kg | 23,11 m³ / day | 13,02 kgBOD / day | 11 kW |

| MSD-III/320 | 4,210 x 2,870 x 2,408 | 377 | 5.385 kg | 26,40 m³ / day | 15,08kgBOD / day | 11 kW |

| MSD-III/400 | 4,810 x 2,870 x 2,408 | 471 | 6.860 kg | 33,01 m³ / day | 18,84 kgBOD / day | 11 kW |

We don’t just offer standard units; we can also create custom-made units to meet your specific needs. Feel free to reach out to us for more information on our custom options. We are always available to discuss tour requirements and provide tailor-made solutions.

Join us in safeguarding the environment and embracing a sustainable future while enjoying the benefits of our efficient and reliable biological sewage treatment systems. Holland Marine Services Amsterdam is your trusted partner in maritime excellence.